Top Countries in Aerospace 3D Printing – Patent Filing Trends

Top Countries in Aerospace 3D Printing – Patent Filing Trends: 3D printing (also known as additive manufacturing) is a highly customizable manufacturing technique that turns digital 3D models into solid objects by building them up in layers. This technology was first invented in the 1980s and is regarded as a fairly recent technology that has been used for rapid prototyping.

We all know that 3D printing is entering in a wide array of industries such as aerospace, dental, toys, medical, architecture, etc. Its popularity can be attributed to the fact that it is not only cheaper in comparison to the conventional methods, but also takes a significantly less time in obtaining solutions for producing large and small products in bulk. Let us take a closer look at the current patent filing trends in this technological field and the countries that are taking advantage of 3D printing in the Aerospace domain.

Table of Contents

Top countries in Aerospace 3D printing based on their patent activity:

- United States of America

- Germany

- China

- United Kingdom

- France

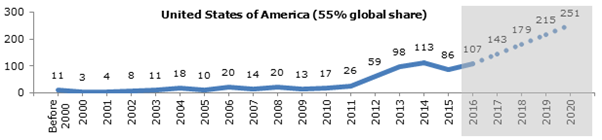

United States of America:

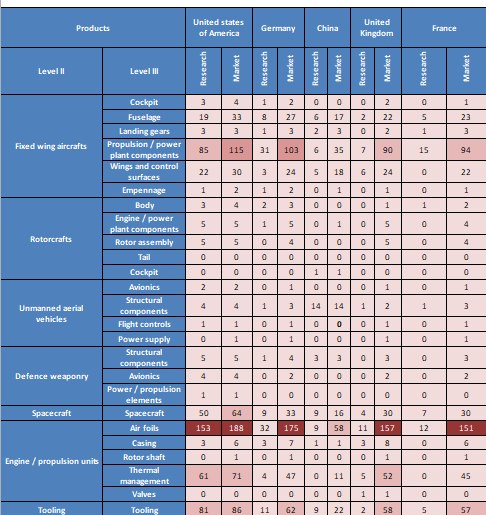

USA has filed 55.14% of all patents that has been filed in “3D printing in aerospace” domain till 2019. Of these patents, only 35.9% patents has their focus on aerospace parts/components like aircraft components (wings, body, structural components etc.), UAVs components (avionics, flight control etc.), spacecraft components, defence weaponry and tooling. This means that the organizations, academia and independent inventors in USA mainly focus on improving gas turbine engine components (in particular – air foils (blades or vanes), BOAS, fuel injectors and fuel lines, turbine shroud and combustor liners).

Overall the focus of these inventions lies in providing solutions for the following which includes but is not limited to:

- Ineffective Manufacturing Method (23.3%);

- Low Component Efficiency (22.5%);

- Improper Heat Transfer (11.5%);

- Difficulty In Manufacturing Complex Geometries (11.1%);

- Costly Manufacturing Process (7.21%);

- Unitary Part Manufacturing (6.89%);

- Time Consuming Process (5.95%);

- Improvement In Physical Properties (5.48%);

- Increased Component Weight (4.54%);

- Ineffective Repairing Method (2.19%); and

- Improvement In Properties Of Material (1.56%).

Around 67% of patents filed before 2000 were focused on aircraft engine/gas turbine engine components, particularly those involved in improving the efficiency of gas turbine blades. There was less focus on metals (33%), instead metal alloys (60%) and ceramics (47%) were used. Between 2000 and 2010, a significant use of 3D printing (particularly SLA, FDM and SLS) was made for manufacturing tools (casting moulds).

The number of patent filing increased drastically from 2011 to 2014 (from 26 patents in 2011 to 113 in 2014). It was observed that this number was significantly declined post 2014. One reason could be that the patent filings of United Technologies Corp. have declined from 62 in 2014 to 37 in 2016. The patent disclosed between the year 2011-2014, mainly focused on aircraft engine/gas turbine engine components like heat exchangers, combustors liner, fuel elements, BOAS (blade outer air seals), air foils (blades and/or vanes) etc. using additive manufacturing techniques; particularly SLS (28.7%), SLA (14.2%), SLM (20.3%) and EBM (32.8%). The materials under consideration were metals and metal alloys (particularly, aluminium titanium, nickel, cobalt and copper metal or alloys).

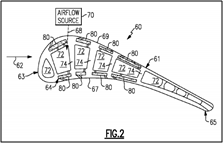

It is noteworthy here that, in the year 2015 and 2016, United Technologies and General Electric has filed significant number of patents (23.9% and 36.4% respectively) that focuses on cooling of hot gas path components of gas turbine engine like air foil (blade and/or vane), shroud, combustor liner, turbine bucket, etc. An example patent showing production of such components and the technical problems associated with them is shown below:

- Patent US20170159447 provides solution for the problem associated with components of a gas turbine engine that include cooling schemes for circulating airflow to cool the component during engine operation. But, known cooling schemes are inefficient and lack structural integrity.

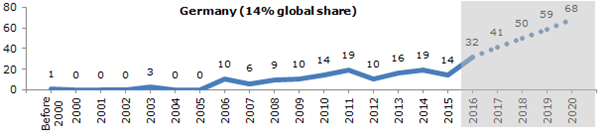

Germany

The main focus of inventions in Germany lies in aircraft engine/gas turbine engine components like sealing devices, safety devices, air foils, blades, vanes and impellers using mostly metal alloys as material and SLS and SLM as 3D printing techniques. Germany has experienced an average growth rate of 18.4% in patent filings from year 2003 to 2016. There is a sudden increase in the number of patent filings in the year 2016. The reason behind this seems be the fivefold increase in the number of patent filings of MTU Aero Engines from 4 patents in 2015 to 20 patents in 2016.

Through the analysis of all patent literatures filed by MTU aero engines, it can be seen that apart from the patents that focuses on gas turbine engine parts like air foils (particularly, blades), turbine disc, sealing device, thermal control gap component etc., a significant number of patents has been filed that focuses on general applications of parts/components in aerospace sector. Here, it can be interpreted that MTU Aero Engine is realizing the white spaces in the field of gas turbine engines, thereby improving its patent portfolio.

A case study has been disclosed below where we can see how the technology has developed in a patent by eliminating problems in prior art:

>> DE102016212080 <<

- Prior Art: The patent disclosure provided a disadvantage of the known additive layer manufacturing. Many materials must first be heated to merge them reliably and to sinter. But this method of producing articles from additive manufacturing technique, often suffers the dimensional accuracy of additively manufactured component region or component.

- Solution: The patent disclosure provided solution for the above problem by providing an “online temperature compensation” for each layer. This is done by acquiring the data for temperature or temperature distribution of the material via an image. The data is then processed to determine the thermally induced expansion or shrinkage of the material and for determining and adjusting the exposure strategy in the portion of such layers. The solidification of the following component layer (s) is then adjusted according to the exposure strategy and exposure webs. In this way, a significantly improved dimensional stability of the manufactured component or additive component region is achieved.

China

Unlike USA and Germany, patents originating from China have diverse focus. Here, patents are filed for parts/components of fixed-wing aircrafts, unmanned aerial vehicle, spacecraft and rotorcrafts (in some cases). Remaining patents disclose parts like hinge chuck for releasing the damping mechanism of the hinge, complex high strength parts, and aviation light guide plate and spindle bearings for aerospace applications.

Parts/components for fixed wing aircrafts include but is not limited to aircraft wing, the aircraft door, trunk, cabin partitions, cabin deck, aircraft housing structure, the joint structure of the wing panel, wing rudder frame and the wing rudder skin in one piece and aircraft gas turbine components like combustion chamber, blades, vanes, turbine disk, etc.

Surprisingly, in the year 2016, most of the patents were filed for UAVs parts/components which included but is not limited to:

- Quadcopter modular rack;

- Upper cover and a bottom plate of lighting control controller for fixed-wing UAVs;

- Conductive layer having two terminals and is embedded in the frame of four-axis quadcopter;

- Upper deck of the nacelle UAV plant protection comprising flying UAV flight control, a receiver, a wireless module;

- Front suspension rod, one-way joints, tees, the clip mount bearing for fixed-wing UAV landing gear field crop canopy;

- Front section of the fuselage, a middle section, and a rear section of the fuselage, the fuselage tail vertebra, two wings, two horizontal tails and one vertical tail of an unmanned aerial vehicle; and

- Drone frame, etc.

United Kingdom

UK also focused towards 3D printing in aerospace domain and they are also growing market for 3D printing technology. In the UK, less emphasis is placed on reducing aircraft engine weight as compared to other aircraft structural components. The USA, the UK, Germany, France and Bulgaria are the main market focus of the company. During the period 2011-2016 patent filing increases to 10.5 times to the number of patents filed till 2010 in the USA. Airbus conducts most of its research in Germany, and its main markets are Germany, the USA, the UK and France. The main market focus for Honeywell is primarily the USA, the UK, Germany, Switzerland and Liechtenstein. Of all the patents filed by Honeywell, 100% are deposited in the USA, 65.4% are deposited in the UK, 61.5% in Germany and 57.7% in both Switzerland and Liechtenstein.

UK also focused towards 3D printing in aerospace domain and they are also growing market for 3D printing technology. In the UK, less emphasis is placed on reducing aircraft engine weight as compared to other aircraft structural components. The USA, the UK, Germany, France and Bulgaria are the main market focus of the company. During the period 2011-2016 patent filing increases to 10.5 times to the number of patents filed till 2010 in the USA. Airbus conducts most of its research in Germany, and its main markets are Germany, the USA, the UK and France. The main market focus for Honeywell is primarily the USA, the UK, Germany, Switzerland and Liechtenstein. Of all the patents filed by Honeywell, 100% are deposited in the USA, 65.4% are deposited in the UK, 61.5% in Germany and 57.7% in both Switzerland and Liechtenstein.

France

France is the main market focus of the companies when it comes to patent filing in this domain. The patent filing for France has shown constant rise since year 2010. Mostly patent were focused on technical challenges such as ineffective manufacturing method, low component efficiency and difficulty in manufacturing complex geometries. 3D printing technologies such as selective laser sintering (SLS), selective laser melting (SLM) and electron beam melting (EBM) were highly utilized in manufacturing of parts.

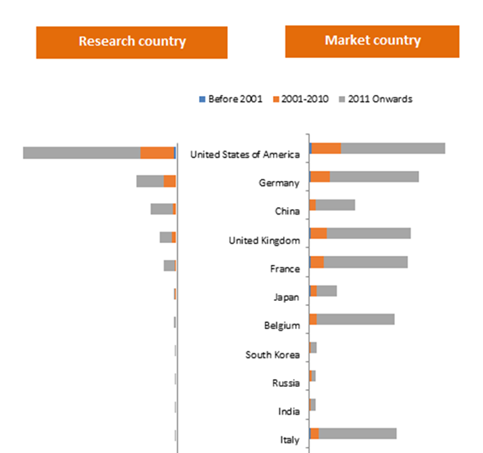

Market Countries

Market geographies are the countries in which the technology of the patent is expected to be utilized. A country is considered as market geography for a patent family if at least one member of the family is filed in that country.

Research Countries vs. Market Geography

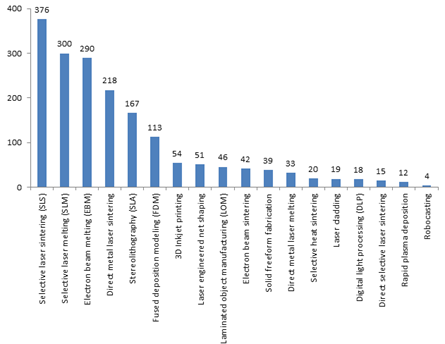

Focused 3D Printing methods in the above-mentioned countries:

- Selective laser sintering (SLS):

The SLS technique is used mainly for manufacturing aircraft engine/gas turbine engine components like air foils, blades, vanes, heat exchangers and fuel system parts (like fuel nozzles, injectors and fuel lines) using metals and/or metal alloys such as titanium or nickel alloy (usually INCONEL). A significant use of this technique was made for manufacturing tools like cores, drill templates and clamping devices, etc. until 2010.

- Stereo lithography (SLA):

This technique was originally used to manufacture tools such as cores for casting, dies, reference standards, drill templates and models (especially between 1999 and 2009). The data analyzed shows that most of the researches involving the SLA technique (73.1% of its patents) are carried out in the U.S.

- Selective laser melting (SLM):

Overall, this technique is generally used to manufacture air foils, blades, vanes, heat exchangers, fuel system parts like fuel nozzles, injectors and fuel lines using mostly titanium, nickel, aluminium, copper, cobalt metals and/or their alloys. However, MTU Aero Engines largely uses SLM techniques (67.8% of its total patents filed in this domain) in order to manufacture aircraft engine/gas turbine engine components like blades, vanes and other components such as sealing devices, bearings, seals and shroud pressure vessels.

- Electron beam melting (EBM):

This technique is mainly used for manufacturing gas turbine engine components like blades, vanes, air foils, etc. but since 2013 there has been a shift in the focus of its use, aside from making turbine blades and vanes. It is now also used to manufacture fuel system parts like fuel nozzles, fuel lines, fuel injectors and other components such as sealing devices, bearings, seals and shroud pressure vessels.

The data analyzed shows that the research involved in this technique (62.1% of its patents) is carried out mostly in the U.S. (most notably by United Technologies Corporation).

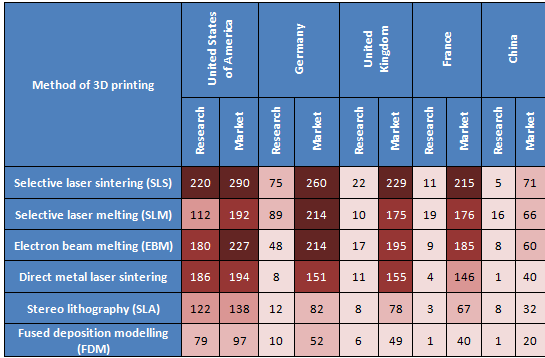

Method Of 3D Printing V/S Top Countries

Product vs. Top Countries:

Final Thoughts

This 3D-Printing revolution began in 2014, when a survey of over a 100 manufacturing companies revealed that 11% of them had already switched to volume production of 3D printed parts or products. According to our understanding and gauze, we judge a particular technology to be mainstream when it reaches an adoption level of over 15%. Numerous companies in multiple industries are ramping up production in this way and we are confident that 3D printing is ready to emerge from its nascent stage to become a viable alternative to conventional manufacturing in multiple industries for various applications. More companies will follow the major players and with this revolutionary shift, companies should start engaging strategically to improve their offerings, revisit their operations and assess the implications it could have on the commercial ecosystem as a whole.

Need to know more about the charts and stats, how 3D printing can boost Aerospace industry? Our technical team is well equipped to solve your queries. The reports are customised to include desired information that is related to patent filing trends, top countries, new entrants, universities, top inventors, mergers, acquisition, litigation, key players, major assignees and many more aspects related to this domain. Our report will lead you in the analytics of this domain that might boost your business as well. For details regarding the report contact us.

– Bharat Saxena (Engineering) and the Editorial team

Having Queries? Contact Us Now!

"*" indicates required fields